What Is A Circular Saw?

What Is A Circular Saw

Ever wondered how those smooth, precise cuts are made in woodworking projects? It’s all thanks to the trusty circular saw. This versatile tool has become a staple in the workshop, offering efficiency, precision, and a whole lot of power.

So how does it work?

Imagine a spinning blade, slicing through wood like a hot knife through butter. It’s a simple concept, but the results are anything but. Circular saws are equipped with serrated blades that rotate at high speeds, effortlessly cutting through wood, plastic, and even metal (with the right blade, of course).

One of the biggest advantages of circular saws is their efficiency. Unlike traditional saws that require back-and-forth motions, circular saws offer a continuous cutting action. This means faster cuts, less effort, and more time to enjoy your project.

Where did it all start?

Believe it or not, circular saws have been around since the 18th century! Originally used in sawmills, they quickly gained popularity for their ability to cut wood efficiently. Today, most circular saws are powered by electricity, offering impressive cutting power and ease of use.

There are two main types of circular saws: desk-mounted and handheld. Handheld saws are the most common and are perfect for a variety of tasks. They typically have blades that spin at around 5000 revolutions per minute (rpm) and allow you to adjust the blade depth and cutting angle to suit your needs.

Safety first! Circular saws are powerful tools, so it’s important to use them responsibly. Always wear protective gear like safety glasses and gloves, and follow the manufacturer’s instructions. With a little care and practice, you’ll be cutting like a pro in no time.

So, whether you’re a seasoned pro or just starting out, a circular saw is an essential tool for any workshop. Its versatility, power, and efficiency make it a must-have for anyone who loves to work with wood.

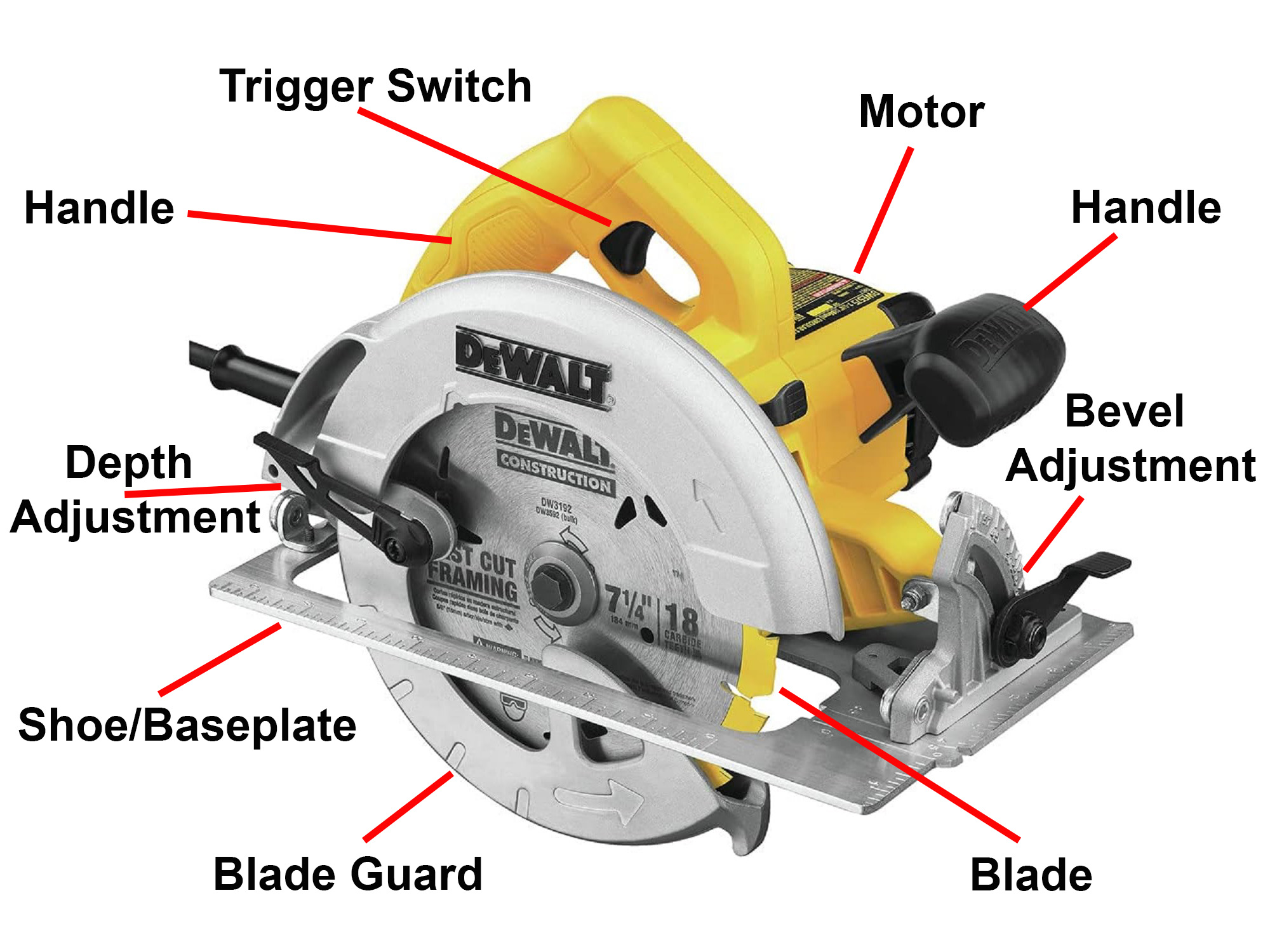

Components of a Circular Saw

A circular saw, while seemingly simple, is composed of several crucial components that work together to deliver precise and powerful cuts. Let’s break down each part and its function:

Blade: This is the heart of the saw. It’s a circular, serrated blade that spins at high speeds to cut through materials. The type of blade you use will depend on the material you’re working with.

Blade Guard: Safety first! This protective cover shields the blade when the saw is not in use, preventing accidental contact. Some blade guards are retractable, allowing for better visibility during cutting.

Shoe/Baseplate: This flat baseplate slides along the material you’re cutting, ensuring a smooth and even cut. It often has a guide rail or laser pointer to help maintain accuracy.

Handles: Circular saws typically have two handles: a top handle for stability and a front handle for guiding the saw. These handles provide control and comfort during operation.

Bevel Adjustment: This feature allows you to adjust the angle of the blade relative to the baseplate. This is useful for making angled cuts, such as bevel cuts or mitre cuts.

Depth Adjustment: This setting controls how deep the blade can cut into the material. You can adjust it to match the thickness of the material you’re working with.

Trigger Switch: This is the power button. Simply press and hold it to activate the saw.

Understanding these components will help you operate your circular saw safely and effectively. Remember, always follow the manufacturer’s instructions and wear appropriate safety gear when using power tools.