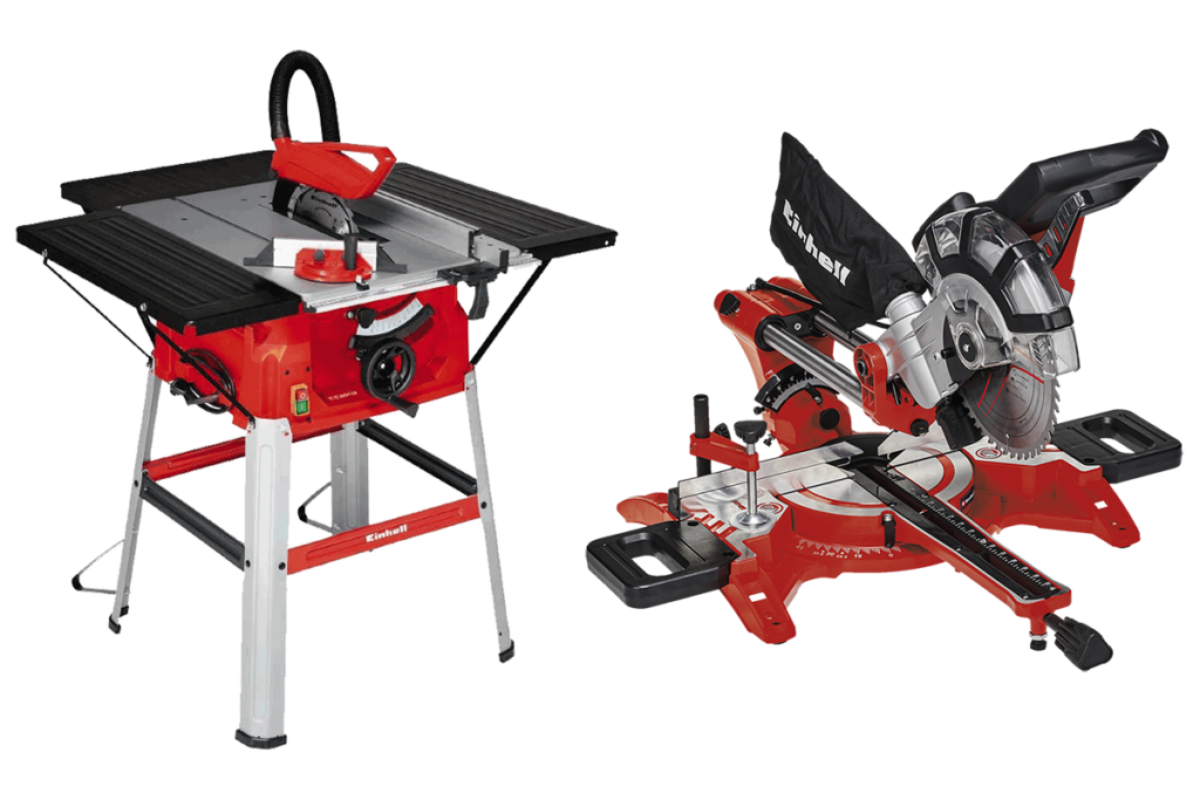

Table saw vs mitre saw

Choosing between a table saw vs mitre saw depends on the type of woodworking projects you plan to tackle and the specific cuts you need to make. Here’s a comparison to help you decide which tool might be best for your needs:

Table Saw

Advantages:

- Versatility: Excellent for making straight cuts, rip cuts (cutting along the grain), crosscuts (cutting across the grain), and bevel cuts. It can handle a wide range of materials and sizes.

- Cutting Capacity: Can cut larger pieces of wood and sheet goods, like plywood and MDF, due to its larger table surface and extended fence.

- Precision: Equipped with a fence system and miter gauge, allowing for precise and repeatable cuts.

- Types of Cuts: Capable of performing dado cuts (grooves) and rabbets (notches) with the right blade and setup.

Disadvantages:

- Size and Portability: Generally larger and heavier, which makes it less portable compared to a miter saw.

- Setup Time: Requires more setup for certain cuts, such as changing blades or adjusting the fence.

- Safety: The blade is exposed, so proper safety measures are essential to prevent accidents.

Miter Saw

Advantages:

- Precision: Ideal for making accurate crosscuts and miter cuts (angled cuts) quickly and easily. Often used for trim work, molding, and framing.

- Portability: Typically more compact and easier to transport compared to table saws, making it suitable for job sites and tight spaces.

- Ease of Use: Generally easier to use for angled cuts and repetitive crosscuts. Many models come with a laser guide to improve accuracy.

Disadvantages:

- Limited Cut Capacity: Usually has a smaller cutting capacity compared to a table saw, making it less suitable for large sheet goods or wider boards.

- Specialization: Primarily designed for crosscuts and angled cuts, not as versatile for different types of cuts or larger pieces of material.

When to Use Each:

-

Table Saw:

- When you need to rip large sheets of wood or make precise, long cuts.

- For projects requiring versatility in cut types and sizes.

- Ideal for creating dados, rabbets, and other specialized cuts.

-

Miter Saw:

- When you need to make accurate crosscuts or angled cuts, such as for trim work, moldings, and framing.

- For smaller pieces of wood or when working in confined spaces.

- When you need quick and precise miter cuts for picture frames or decorative work.

Conclusion:

Both tools have their strengths and ideal use cases. If you need a versatile tool that can handle a range of cuts and large materials, a table saw is the better choice. If your projects focus on precision cuts for trim work, angles, and smaller pieces, a miter saw might be more suitable. Many woodworking shops benefit from having both tools to cover a wider range of tasks effectively.

Recommended by Tool Guide Pro

No products found.

No products found.